Global Manufacturer and Supplier of Wire Marking and Labeling Systems Since 1989.

Exceptional products, fast delivery, and personalized customer service

Enjoy genuine personal service.

Experience the unmatched durability of our products.

When possible, we manufacture and source our products from the USA.

Our responsive team swiftly delivers tailored solutions, ensuring your needs are met with timeliness and unwavering efficiency.

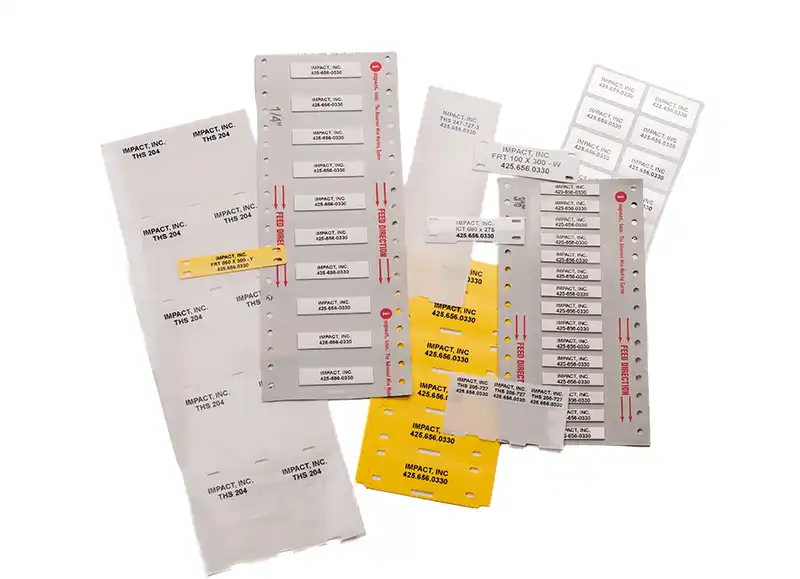

Most Popular Products

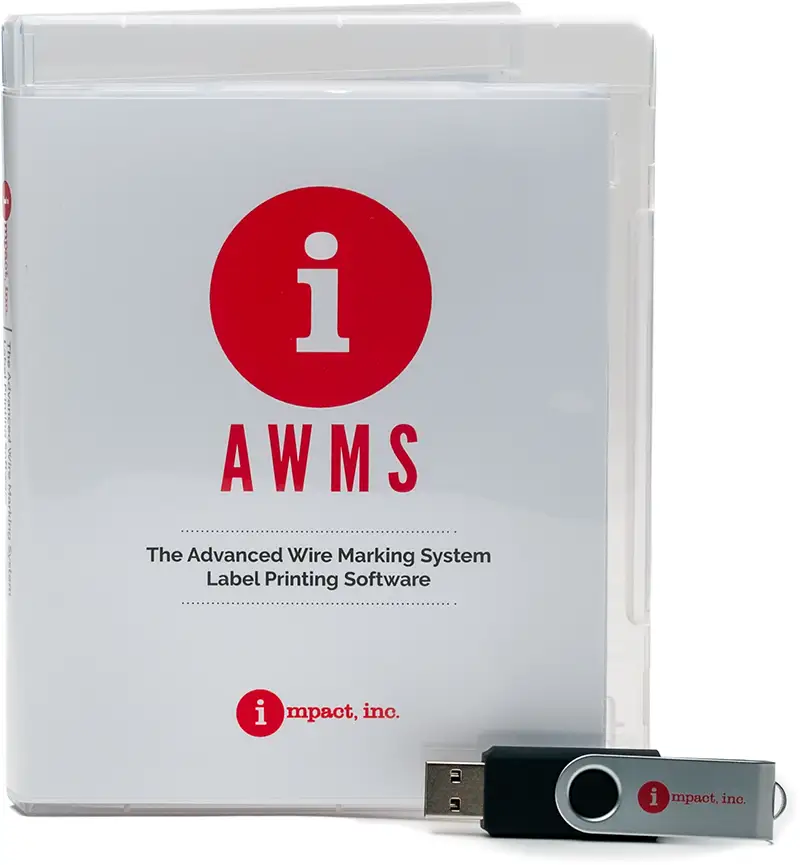

Free Software

Experience the Impact, Inc. Difference

With the purchase of the AWMS-245 Plus Printer, you'll receive a complimentary software. This user-friendly software is capable of printing on a wide range of labels, including AWMS Heat Shrink Wire Markers. Plus, take advantage of our free technical support during business hours for maximized printing capabilities.

Featured Services

What is everyone saying?

Subscribe for updates

Sign up for all the latest news, special offers, and product info.